Webster | Siemens | Penn Separ | Cannon Boilers | Lockwood Boilers | Sterlco | Spirax Sarco | Thrush | Van-Packer | United Brass Works

JB Series Burners

(400 – 12,600 MBH Input) Our JB Series Burners are highly configurable, robust, forced draft burners for boilers and thermal fluid heaters. They are capable of firing a combination of gas, oil, renewable or alternative fuels. These burners are also capable of achieving low NOx levels for industrial watertube boilers, thermal heaters and firetube and commercial watertube boilers.

EJB Series Burners

(400 to 2,500 MBH Input) The Webster EJB Series Burners offer years of dependable and economical operation. Designed with economy in mind, Webster EJB burners are durable and easy to start up and service. Our exclusive flame retention head design maintains stable and efficient combustion in a wide variety of furnace configurations and conditions.

_burners.jpg)

JBS and JBS(X) High Swirl Burners

(2000 – 5,500 MBH Input) JBS and JBS(X) High Swirl Burners reduce emissions while providing higher turndowns. With turndown rates as high as 12 to 1 for Natural gas, JBS and JBS(X) High Swirl Burners offer industry leading combustion efficiency with low excess air. Webster's advanced head design is unique in its ability to provide dual manifolds to handle multiple fuels for challenging alternative fuel applications.

_boiler_burner.jpg)

JBE(X) Series Burners

(8,400 – 74,000 MBH Input) Webster’s JBE(X) Boiler Burner is a high efficiency, low excess air burner that incorporates a unique high swirl firing head to improve commercial boiler combustion efficiency. Perfect for hospitals, schools and universities, which are particularly cost sensitive because of tight operating budgets, the JBE(X) achieves boiler horsepower ratings in the 200 to 1,750 HP range using less fuel and electricity than conventional burners.

HDRV Series Burners

(12,600 – 40,300 MBH Input) Our HDRV Series Burners extends Webster's capacity to deliver superior combustion performance for larger commercial, institutional, and industrial applications. The HDRV is offered in several orientations and configurations and are capable of firing a combination of gas, oil, renewable or alternative fuels. These burners are also capable of achieving low NOx levels for industrial watertube boilers, thermal heaters and firetube and commercial watertube boilers.

HDS Series Burners

(12,600 – 69,000 MBH Input) The HDS Series Burners offers improved emission performance and higher turndowns (12 to 1 on Natural gas). The HDS uses a unique housing with low excess air requirements and high swirl firing head to provide great fuel/air mixing and superior combustion performance for firetubes, watertubes, and industrial applications. The HDS can be configured as an HDSX where low NOx is required.

HDR-RF Series Burners

(46,000 – 200,000 MBH Input) The HDR-RF Burner is a full register burner for industrial applications with high efficiency remote fan. It is available as a standard gas and/or oil fired burner and as a low NOx burner (HDRSX-RF). It supports a wide range of fuels and is recommended for large firetube and industrial watertube applications.

HDRMB Series Burners

(4,100 – 25,400 MBH Input) The HDRMB Burner is available for ultra-low NOx applications in capacities ranging from 125 to 2,500 boiler horsepower, and can fire a wide range of fuels, including: Natural, LP, and Bio Gases, as well as No. 2 Oil, Amber 363, or Low Sulfur Diesel for applications requiring a back-up fuel. Guaranteed emissions for the HDRMB are as low as 9ppm NOx and 50ppm CO when firing natural gas.

_and_hdf(X)_burners.jpg)

JBF(X) and HDF(X) Series Burners

(420 – 20,900 MBH Input) With the introduction of the JBF(X) and HDF(X) series burners, Webster has added the ability to achieve single digit NOx emissions without the use of Flue Gas Recirculation (FGR). The new JBF(X) and HDF(X) burners utilize fiber mesh, surface combustion technology that covers a range from 10HP up to 500HP.

.jpg)

FDR(X) Series Burners

(15,000 – 200,000 MBH Input) Webster’s FDR(X) Forced Draft Register burner is a highly efficient combustion system that combines a windbox, air register, ignition assembly, fuel train, flame safety control, combustion control, FGR (Flue Gas Recirculation) system, and a forced draft blower, all assembled into one complete packaged unit.

LMV5 Linkageless Burner Management System

The LMV5 Linkageless Burner Management System sets the standard high - from easy installation, programming and commissioning to reliable, proven control. With the LMV5, Siemens forges new ground delivering a fully integrated system that is not only easy to install and use, but also provides improved burner performance and efficiency and ensures safe operation.

- Fuel to air ratio curve can easily be adjusted at any point in the firing rate.

- 15 programmable points, with 4 independent positions including pre-purge, ignition, post-purge and standby.

- User friendly menu system for fast programming and commissioning.

- Worldwide approvals and technical support.

The LMV51 integrates linkage control, burner flame safeguard, and modulating PID control, controlling up to 3 actuators simultaneously.

The LMV52 additional offers optional O2 trim and/or VFD control. The LMV52 controls up to 5 actuators simultaneously for optimal efficiency in low NOx burner applications.

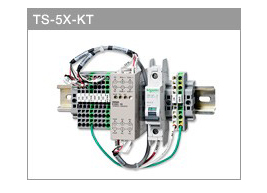

Touchscreen Kits

TS… series Touchscreen Kits provide an interface with the Siemens LMV3 or LMV5 linkageless control. Preprogrammed, pre-tested kits include first-out annunciation, BMS communications, and enclosure options.

Master Panels

TS-MS… series Master Panels provide Lead-Lag control for up to eight boilers with LMV or RWF controls and an additional DA Panel. Master Panels optimize the control and modulation of boilers to meet demand and maximize efficiency.

- 7.5”, 10”, or 12” Touchscreen options.

- TS touchscreen kit or serial communication kit at each boiler.

Flexible communication interface options to the building management system (BMS) provide streamlined data collection, monitoring and control.

LMV Combustion Enclosures

A TS-CE… Series Combustion Enclosure with Siemens LMV linkageless controller provides easy installation for combustion control and monitoring technologies. Standard options include:

- LMV linkageless system.

- RWF55 for load control or water control.

- 6” or 10” touchscreen.

- PLC annunciation.

- BMS communication.

- 3 phase for blower, oil pump, or air compressor motor starter.

Flexible communication interface options to the building management system (BMS) provide streamlined data collection, monitoring and control.

Protocol Converter

TS… series Protocol Converter provides a flexible communication interface to the building management system (BMS) for streamlined collection and monitoring. Supports LMV3, LMV5, RWF55, and all TS… Series Lead Lag Master Panel, Touchscreen Kits, Combustion Enclosures, and Deaerator/Surge Panels.

- Converts Modbus/RTU to BACnet/IP, BACnet MS/TP, Metasys N2, Modbus TCP/IP or LonWorks.

- Allows simultaneous connection of up to 64 devices via serial connections.

- Allows simultaneous connection up to 12 TS… Series devices via Ethernet Modbus.

Flexible communication interface options to the building management system (BMS) provide streamlined data collection, monitoring and control.

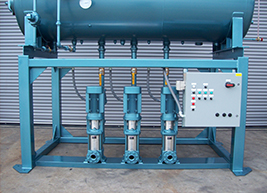

Deaerator/Surge Control System

A TS-… Series Deaerator / Surge control system manages lead/lag operation of an individual deaerator (DA), surge, condensate, or a combination DA and surge/condensate tank for up to six pumps. The menus provide straightforward commissioning and operation.

Each TS-… control system includes a preprogrammed 6” or 10” touchscreen, a programmable logic controller (PLC), and digital and analog signal inputs for monitoring and control.

- Graphics for individual pump status and automatically configured overview screen.

- RWF55.50A9’s for DA level control, Backup DA level control, DA pressure control, or Surge tank level control.

Control an individual deaerator, a surge tank, or a combination DA-surge split tank, with the ability to manage a separate DA and a surge or condensate tank with one TS- Series control panel.

Serial Communication Kit

A TS… series serial communication kit connects a LMV linkageless control to a Master Lead/Lag Panel (TS-2000) without a local touchscreen at each boiler.

Electronic Water Level Control System

The Siemens Electronic Water Level Control System maintains a consistent water level, which is crucial for efficient, reliable boiler operation. The Siemens Modulating Water Level Control System offers the following advantages.

- More efficient boiler operation.

- Minimal boiler water carryover.

- Reduced thermal shock to boiler.

- Reduced feedwater pump wear.

For boilers with rapidly fluctuating steam loads, the Siemens system has the capability to include dual-element control, minimizing boiler drum swell and shrink effects.

Valve-Actuator (VA) assemblies

SCC offers a full complement of Valve-Actuator (VA) assemblies.

Variable Frequency Drives

SCC offers Variable Frequency Drives preprogrammed for the LMV linkageless application. A VFD is another option from SCC which provides a simple method for burner operational savings. Incorporated with a LMV5, a VFD control with actual motor RPM speed sensor provides reliable, efficient and safe control of the combustion air blower.

Double-Valve Bodies

Compact VGD40… double-valve bodies consist of two safety shut-off valves in series. Each individual safety shut-off valve has double seats to achieve high flow. Patented seat construction with individual closing spring for each seat to assure reliable shut-off and high close-off pressure rating.

Gas Valve Actuator

SKP55 & SKP75 Air/Gas Ratio Controlling Gas Valve Actuator.

- Excellent control for recuperative burners, burners utilizing preheated combustion air, and variable orifice/flow regulating burners.

- Air/gas ratio maintained even when air flow is disrupted.

- Safety shut-off control and pressure regulation in one compact unit.

- Compensates for variations in combustion chamber back pressure.

- Low-fire, excess-air biasing adjustment.

- Simplified commissioning of burner and reduced start-up time.

- Optimal solution for premix burner applications.

Blowdown Separators

Intermittent Boiler Blowoff, Hydronic S.R.V's, and other Process Blowdown. The modern and efficient way of handling boiler intermittent blowdown. Separators have also been used for hydronic safety relief valve discharges, deaerator overflows, autoclave draining, and other high flow pressurized condensate to drain applications. The smaller diameter takes up less space then a traditional blowoff tank while providing an efficient separation of flash steam and condensate.

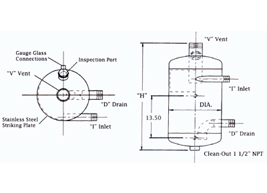

Flash Separators

Flash Tanks for Handling Condensate and Flash Steam Recovery Penn Flash Separators use a tangential inlet and cyclonic action to instantly separate steam and condensate. Our Flash separators are smaller in size and more efficient then traditional flash tanks. Because of the unique smaller size they are less expensive then traditional flash tanks. The clean steam can be returned to a lower pressure saving valuable BTU's and makeup water. Return on investment can be in a matter of weeks. Easy to use flash steam and selector charts assure proper sizing of a Flash Separator for your condensate requirements. Special tank designs are also available. Penn Separator has over forty years of experience building pressure vessels to ASME Code. All Penn Flash Separators are constructed to the ASME Code Sec. VIII.

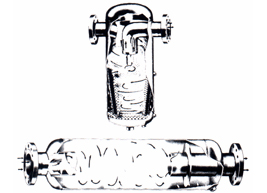

Inline Entrainment Separators

Inline Centrifugal Entrainment Separators for Steam, air, and Other Gases

Penn Inline Separators create a centrifugal spinning action that separates out liquid entrainment droplets in steam, air, or other gases. Each are Inline type designed to fit in existing piping.

Exhaust Silencers

When steam air and other gases are vented to atmosphere at high velocities noise is created. Typically the higher the velocity the louder the noise level. Penn makes two models of exhaust silencers to reduce noise levels.

Heat Recovery Systems

Continuous Blowdown Heat Recovery

Complete packaged heat recovery system in a smaller single vertical tank design. Ten different Pre-Engineered systems for small to medium sized boilers with continuous blowdown of 1 to 30 gpm and make-up capacities of 9 to 150 gpm in a self-contained unit. This system can provide up to 90% heat recovery from the continuous blowdown.

Ultramizer

Cannon has obtained exclusive rights to the technology for the Ultramizer from the Gas Technology Institute (GTI). The Ultramizer's technology can be used on any clean fuel boiler to raise the efficiency to near 95% and also allows the return of clean water to the system.

Feed Water Heater

A unique economizer designed to recover your exhaust stack energy and save you thousands of dollars each year. Cannon Feedwater Heaters pay for themselves by reducing your fuel bills. We will provide you with an estimated payback period when you inquire, and it is normally less than one year.

Condensing Economizers

In application the two are one-in-the-same, since they both recovery heat from an exhaust stream and return it to a colder water stream. The difference is the temperature range in which the economizer is operated. Our unit may look identical in outward appearance, but can be used in a condensing application if originally design to do so.

On-Demand Economizers

Economizers have been proven money saving concepts for nearly 100 years. Now we can extend the efficiency of the traditional rugged Feedwater Heater style economizer, with less impact on your boiler room than the standard installation. Cannon's On-Demand unit now converts waste gas heat to free energy for your process, with minimal effect on any other piece of equipment in your facility.

90% Efficiency

Much is being advertised these days concerning new equipment to boost industrial steel boiler efficiency to the 90% range, something that was unheard of decades ago. But all new equipment may not be need to achieve this goal.

Heavy Duty Economizers

Cannon economizers are custom designed for optimum heat recovery and service life for your unique application. Cannon will design your economizer for gas, oil, coal, wood, or special waste gas streams. These units are available in open lattice or bulkhead tubesheet designs, and Cannon manufactures the nickel-brazed helical finned tubes used in all of our economizers.

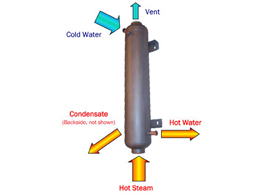

Vent Condensers

The vent condenser is a plume abatement device that provides a visual improvement, as well as reducing water/ice or corrosion near the steam vent. Vented steam is directed into the unit and condensed by cold water, and energy is continuously recovered at a rate of 970btu's for every pound of steam. This hot water and clean distilled condensate are then ready for use elsewhere in your operation.

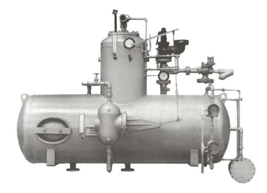

Steam Accumulator

A steam accumulator is a smart method to reduce severe boiler loading and cycling, when short- duration, high flow steam is required. An accumulator can reduce the fuel consumption and increase the service life of your boiler by stabilizing its operating conditions.

Custome Heat Exchanger

Cannon has full capabilities to design, build, rebuild, or repair your heat exchanger. We are experts in our ability to solve customers' problems through innovative design and material solutions.

http://www.lockwoodproducts.com

Manufacturer of packaged deaerators, boiler feed, and condensate return systems for steam boiler systems used for industrial heating and process applications, industrially, commercially and institutionally.

Condensate Return Systems

- Single and Multi- Pump Configurations.

- Cast Iron & Steel Receivers.

- Available 2 ft. NPSH Pumps.

Boiler Feed Systems

- Complete Low and High Pressure Systems.

- Pump Capacities to 600 BHP and up to 200 PSIG Discharge Pressure.

- Custom Systems Available.

Deaeration Systems

- Pressurized Spray Tray.

- Capacities to 420,000 Lbs/HR.

- Optional Surge Systems Available.

- Complete Packaged Systems.

Pumps

- Centrifugal.

- Turbine.

- Multi-Stage Centrifugal.

K-Series Centrifugal Pumps

The Sterlco K-Series 2' NPSH Pump is designed to pump hot condensate up to 212 degrees Fahrenheit. Stainless Steel construction on the impeller and inducer lengthens the life of the pump and offers supreme corrosion resistance. Engineered to fit Sterlco boiler feed and condensate units or competitive models.

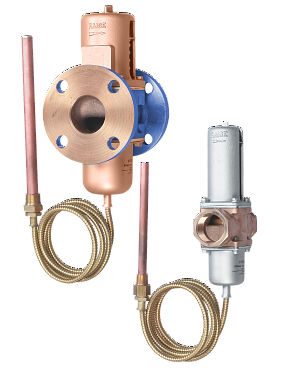

Self Modulating Temperature Control Valves

Simple yet efficient design requires minimum maintenance. Heavy Duty construction assures long valve life. Valves are temperature actuated, self-powered, fully balanced, and applicable to heating or cooling processes using water, oil, steam or other fluids.

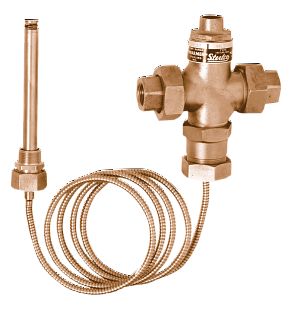

Temperature Actuated Water Regulating Valves

This thermostatic cooling control valve has everything you need for reliable temperature control. The Sterlco 56-T Series Temperature Actuated Water Regulating Valve evenly regulates cooling water and other fluids in the most rugged applications. It is ideal for hydraulic power packaged equipment, hydraulic presses, or wherever reliable performance is required.

Hand Radiator Valves

Sterlco Radiator Valves feature practical, simple styling for your steam or hot water heating systems. The solid, rugged construction assures long serviceable life. Available in several different body patterns, these valves provide flexibility to meet the needs of your application.

Condensate Pumps

Available in Stainless Steel or Cast Iron. 3450 RPM motors assure maximum efficiency while maintaining minimum motor horsepower. Available in a wide range of sizes, these U.S. made pumps have just the right accessories and options to meet your unique needs. What’s more, a nationwide network of stocking distributors means fast, easy, year-round access to pumps and replacement parts.

Boiler Feed Pumps

Available in Stainless Steel or Cast Iron.

For nearly a century, Spirax Sarco has been committed to helping steam users optimize productivity. As America's leading provider of steam system solutions, Spirax Sarco is the recognized industry standard. Our reputation is built on our vast knowledge of steam applications. We believe steam efficiency is a vital component of productivity. For you, efficiency in steam usage means savings where it counts.

Boiler Controls

An extensive range of boiler controls and systems is available from Spirax Sarco. Whether it's a new installation or a retrofit application, Spirax Sarco will have the answer.

Flowmeters

Flowmeters for the ultimate in accuracy, reliability and versatility. Suitable for steam, most liquids & gases.

Control Valves

Simple self-acting controls to systems that match highly sophisticated control loops. Every control solution covered in our range.

Steam Traps

Removing condensate and air from your system is essential. Returning condensate to the boiler house maximises use of energy. We have the right steam trap for your application and the people to advise you.

Condensate Recovery

Returning condensate to the boiler house is essential for steam plant efficiency. For applications needing assisted flow we have the right pump for your system.

Strainers

Range: 1/2" to 10"; up to 950 psig; bronze, cast iron, cast steel and stainless steel; flanged and screwed connections.

Humidification

Health & environmental regulations are tighter than ever. Control your humidity - from direct steam injection to self-generative humidifiers.

High Purity

The use of clean or pure steam to reduce the risk of product or process contamination spans many industries. The Spirax Sarco 'clean steam' product range has been designed and manufactured to the highest standards using stainless steel materials. The products are able to withstand the rigors of service demanded by clean steam and other aggressive process fluids, where contamination must be prevented and service life extended.

Liquid Drain Traps

Spirax Sarco offers a wide variety of drainers for removing liquids from gases.

Pipeline Auxiliaries

Clean dry steam is crucial to the longevity and reliability of your plant. Sustain that investment through easy maintenance and visual diagnostics.

Supplying effective, well engineered packaged solutions to suit your needs means you are free to concentrate on your business. We'll manage everything through proposal, design & manufacture to completed package.

Regulators

Spirax Sarco regulators are suitable for steam applications and offer a wide choice of control options. Spirax Sarco Regulators are the best choice where downstream pressure or temperature must be accurately controlled regardless of variations in upstream pressure and steam load condition.

Thrush Co. Inc. manufactures a full line of pumps, heat exchangers, valves and accessories for residential, commercial, and industrial systems. Superior product quality has earned Thrush its leadership position along with personal responsive service, prompt delivery, expert technical support, and a high standard of business ethics. Our worldwide network of representatives and distributors, as well as our in-house service department, are available to meet your needs and insure your satisfaction. When you need heating and cooling products, think Thrush.

Aar-O-Vent

The Aar-O-Vent uses a stainless steel coalescing medium to separate entrained air and dirt particles. The 720 Air Vent, which has been a mainstay in the hydronics industry for decades, has been incorporated for the air elimination portion of this unit. Standard components include site glasses and ASME code vessels. The Aar-O-Vent will be available in sizes 3/4" through 12". Please consult factory if larger sizes or different vessel materials are needed.

Stock Commercial Pressurizers

Thrush pressurizer packages boost pressure to maintain proper flow rates throughout the system. From the top floor down, Thrush booster packages are uniquely engineered to provide constant pressure to the entire building to ensure adequate flow and proper operation of fixtures, appliances and valves.

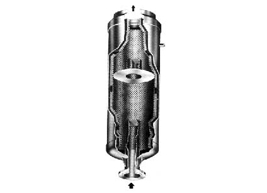

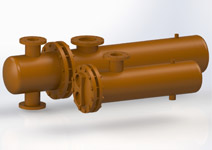

Heat Exchangers

Thrush Co. Inc. manufactures quality shell and tube heat exchangers engineered to meet many applications. They're specially designed for heating or cooling liquids for process systems, heat recovery, and comfort systems using steam or liquids.

Products:- Heat exchangers

- Tube bundles

- Tank heater

Built To Order Packaged Systems

Thrush offers a series of factory-assembled, packaged systems for commercial and industrial applications.

Thrush Packaged Systems Include:- Pressure booster systems

- Heat transfer systems

- Pumping system

- Booster system

- Low water system

HOT-PAK Instantaneous Water Heater

- Steam to water design

- ASME Sec. VIII Division 1 construction

- Copper tubing

- Brass tube bundle supports

- Shell insulation and jacket

- Circulation pump

- ASME pressure relief valve

- High limit temperature switch and solenoid valve

- Water temperature gauge

- Vacuum breaker

- Support stand and base

- Vertical design

Thrush Accessories

Thrush offers a full line of accessories, valves, and fittings to enhance the efficient operation of your hydronic heating, air conditioning, and plumbing systems. Our components have a proven performance record of dependability. At Thrush, we take pride not only in the quality of our products, but also in our customer service. We work closely with our customers, providing expert technical support to help them achieve the most from their hydronics systems. Quality, engineering, and service make the Thrush difference.

Thrush Tanks

Thrush provides a complete line of expansion, hydropneumatic and plain steel tanks.

- Diaphragm Expansion Tanks - 125 PSI ASME

- Bladder Type Expansion Tanks - 125, 175, or 250 PSI ASME

- Diaphragm Thermal Expansion Tank - 150 PSI ASME

- Bladder Thermal Expansion Tank - 150 PSI ASME

- Diaphragm Hydro-Pneumatic Tank - 125 PSI ASME

- Bladder Hydro-Pneumatic Tanks - 125, 175, or 250 PSI ASME

- ASME Shock Arrestors

- Plain Steel Tanks

Since 1944, Van-Packer has been a leader in the chimney field. Over the years Van-Packer has steadily increased its product line to include chimneys to handle applications in all aspects of the commercial and industrial fields. The Van-Packer product line ranges from a small diameter single wall steel to refractory lined UL Listed product through larger diameter engineered freestanding and guyed stacks with linings designed to handle specific operating conditions.

Chimney Systems

- Double Wall 1" to 4" Insulation

- Condensing Systems UL 1738

- Grease Duct

- Refractory Lined

- Incinerator Exhaust Systems

- Engine / Turbine Exhaust

- Engineered Custom Systems

- B-Vent

- Thermal Oxidizers

Double-Wall Positive Chimney and Breeching Systems

Description/Application: Double wall air or optional fiber insulated positive pressure system for venting boilers, kilns, grease ducts, emergency generators, caustic air, coffee roasters, bagel ovens, bread ovens, pizza ovens, and fumes.

- Maximum Temperature Continuous Firing Dual listings of 1000°and 1400°F.

- Maximum Temperature Intermittent Firing Dual listings of 1400°and 1800°F;2000°F for grease duct applications.

- Fuel LP gas, natural gas, #2, #4*, #5*, or #6* fuel oils, wood*, coal*, diesel fuels, grease vapors, caustic fumes, and particles.(*It is recommended that 316 stainless steel liner be specified when using these types of fuels.)

- Inner liner 6" - 36"ID = 20-gauge stainless steel.

- Inner liner 38" - 48"ID = 18-gauge stainless steel.

- Outer shell 8" - 26"OD = 24-gauge aluminized, 304 or 316 stainless steel.

- Insulation DW - One inch air space between shell and liner; DW plus - One, two, three, or four inch fiber insulation.

- Joint Method The liners are flanged and the product comes with joint sealant and vee bands to ensure product integrity is maintained. The outer shells are joined by flanged bands to ensure environmental protection.

- Diameters Available 6" through 48" in two-inch increments are standard.

- DW - 1000°F applications = 4".

- DWplus - 1000°F applications = 2".

- 1400°F applications = 6".

- 1400°F applications = 4".

Grease Duct:

See Installation Instructions

- Model DW and DWplus:6" - 18"ID for 1000°F and 1400°F applications = 2".

- Model DW:20" - 48"ID for 1000°F and 1400°F applications = 4".

- Model DWplus:20"- 48"ID for 1000°F = 2" and for 1400°F = 4".

- Application References & Listings c UL us 103 file number MH11435, NFPA 31, 34, 37, 54, 68, 85A, B, D,96, and 211.

Double-Wall Condensing Chimney and Breeching Systems

Description/Application: Double wall corrosion resistant, for venting negative or positive pressure and gas appliances. Categories II, III and IV venting.

- Maximum Temperature Continuous Firing 550°F.

- Maximum Temperature Intermittent Firing 550°F.

- Fuel LP gas, natural gas.

- Construction Standard Jacket materials:24-gauge aluminized steel or 24-gauge type 430 stainless steel, inner liner 24-gauge type VP1738 stainless steel alloy.

- Insulation One inch air space.

- Joint Method The liners are flanged and the product comes with joint sealant and vee bands to ensure product integrity is maintained. The outer shells are joined by smooth bands to ensure environmental protection.

- Diameters Available 4"through 10"in one-inch increments and 10"through 24"in two-inch increments are standard.

- Clearance To Combustibles 2".

- Clearance To Non-Combustibles 0".

- Application References & Listings c UL us 1738 file number MH45778, NFPA 54 and 211.

B-Vent

For Venting Atmospheric Gas Fired AppliancesDescription/Application: Double wall corrosion resistant, thermal reflective Galvanized Steel outer casing with aluminum inner liner for venting negative or atmospheric pressure gas appliances.

- Maximum Temperature Continuous Firing 470°F.

- Maximum Temperature Intermittent Firing 470°F.

- Fuel LP gas or natural gas.

- Construction Outer casing of galvalume and galvanized, inner liner of aluminum both 24 & 26 gauge.

- Insulation Standard: Outer casing and inner liner separated by an annular air space of 1/2" Insulated: Outer casing and inner liner separated by 1/2" blanket of fiberglass insulation for sizes 4" - 14" diameter.

- Joint Method 3" - 14" are jointed by inserting mating ends together and twisting clockwise16" - 30" have a slip joint involving sheet metal screws for securing joints.

- Diameters Available 3" through 30" diameters.

- Clearance To Combustibles 1".

- Clearance To Non-Combustibles As required by local codes and as permitted by the authority having jurisdiction, CSA B149.1, CSA B149.2, NFPA 211.

- Application References & Listings UL441 file number MH 66M3, ULC file number CMH695, CMHC acceptance number 6952.

Single Wall Fume Hood, Particle Containment, Breeching Systems

A single wall Stainless Steel exhaust system for venting caustic air, fume hoods, particle containment, breeching for boilers and heating appliances.

- Maximum Temperature Continuous Firing 1400ºF.

- Maximum Temperature Intermittent Firing 1800ºF.

- Fuel LP gas, natural gas, #2, #4*, #5*, or #6* fuel oils, wood*, coal*, caustic fumes, vapors, and particle containment. (*It is recommended that 316 stainless steel be specified when using these types of fuels.).

- Construction Diameters: 6" - 36"ID = 20-gauge type 304 or 316 stainless steel 38" - 48"ID = 18-gauge type 304 or 316 stainless steel.

- Insulation None.

- Joint Method All components are flanged and the product comes with joint sealant and vee bands to ensure product integrity is maintained.

- Diameters Available 6" through 48" in two-inch increments are standard. Optional diameters available upon request.

- Clearance To Combustibles As required by local codes.

- Clearance To Non-Combustibles As required by local codes.

- Application References & Listings None.

United Brass Works, Inc. is an ISO9001 company, producing high-quality; pressure-tight red brass casting components for original equipment manufacturers nationwide. As a job shop foundry, Keystone can provide, design, tooling, brass castings, or together with the United Division, cast, machined, tested and/or assembled products.

Ball Valve

- Double Female Ball Valve

- (Complies with MSS-SP110-92)

- 200 lbs. WSP at 406 ° Max

- 400 lbs. WOG

- 100% Pressure Tested

- Threaded Ends

- Blowout Proof Stem

- 1/4” - 1/2” Full Flow

- 3/4” - 2” Large Port Diameters

- 3/CRN OCO7135.2C

Angle Valve

- Metal to Metal Seat & disc

- 125 lbs. WSP at 350 ° Max

- 200 lbs. WOG

- 100% Pressure Tested

- Threaded Ends

- Rising Stem

- Swivel Disc Holder

- *Contains lead. Angle valve not for use in water systems intended for human consumption*

Blow Off Valve

- Model 425 Quick Opening Blow Off Valve

- Class 300

- ANS5I B16.34

- 665 psi Working Steam Pressure @ 500F

- 750 psi @ 100F

- 100% Pressure Tested

- Maximum Boiler Blow-Off Pressure 530 psi

- Threaded Ends

- High Temp. Powder Coating for Corrosion Resistance

- CRN OCO7135.2, 24, 25, 26

- CRN OEO2171.7, 79, 70, 78,7AY, 7T, 7N